Ebike Brushed Vs Brushless Hub Motors

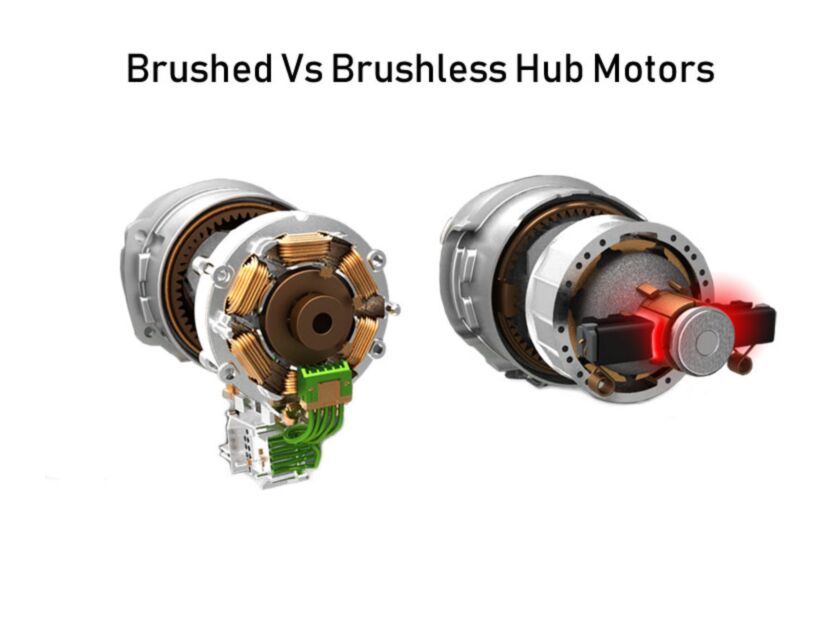

Brushed Vs Brushless Hub Motors

Modern e-bikes all prefer to use "brushless" hub motors, just because they are more durable than the “brushed” counterpart, besides the maintenance cost in them is also very little.

What is the difference between brushed and brushless hub motors?

Brushed Hub Motors

A brushed DC motor uses a configuration of wound wire coils- the armature- acting as a two-pole electromagnet. When the motor is working, the coil and the commutator (a mechanical rotary switch) rotate, the permanent magnets and the brushes do not rotate, and the current direction change of the coil is completed by the commutator and the brush. When the current direction of the coil change, the electromagnet’s poles are changed and push against the permanent magnets along the outside of the motor.

This contact of brushes and commutator wears the brushes that these brushes have to be replaced regularly. This replacement is not so expensive but to manage this work itself is not so easy.

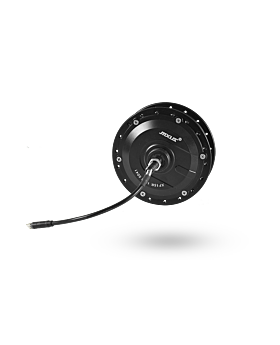

Brushless Hub Motors

A brushless motor utilizes a permanent magnet as its external rotor or internal rotor. In addition, it uses three phases of driving coils and three hall sensors to track the rotor position. When the sensor tracks the rotor position, it sends out reference signals to the controller. Then the controller activates the coils in a structured way – one phase after the other.

The brushless motor adopts electronic commutation, the coil does not move, and the magnetic pole rotates. As there is no physical contact fromany parts of the motor inside, therefore there is virtually no wear and tear possibilities, making the motor’s durability limitless. These motors require sophisticated controllers, and it makes it possible for using three different windings, and power is supplied by individual windings according to the position they are in the movement. When the motor passes one winding, the controller passes the power to another winding, making the movement to continue without stopping.

| Brushed Motor | Brushless Motor | |

| Pro | Low cost. | High efficiency |

| Require a simple and inexpensive controller. | Low maintenance, Long lifespan. | |

| no controller needed for fixed speeds. | Lower electric noise generation. | |

| High-speed range | ||

| Con | Less efficient, poor heat dissipation capacity | High cost |

| Electric Noisy | Require a complex and expensive controller | |

| Regular maintenance and replacement. |

Sign In

Create New Account