What you need to know about Battery Management System (BMS)

What you need to know about Battery Management System (BMS)

A lithium battery is an important part of the electric bike, electric scooter, hover-board, moped, unicycle, or electric tricycle, etc. Some men would like to DIY the lithium battery, some men would like to fix the defective battery to save the cost. Before doing this, you need to know more about the battery management system- the brain of the lithium battery.

Here you will learn.

l What is the Battery Management System (BMS)

l How does Battery Management System (BMS) Work

l How to Choose Battery Management System (BMS)

l How to Connect Battery Management System (BMS)

What is the Battery Management System (BMS)

You could see the instroduction in the former blog.

https://www.elecycles.com/blog/post/what-is-electric-bike-lithium-battery-bms/

How does the Battery Management System (BMS) Work

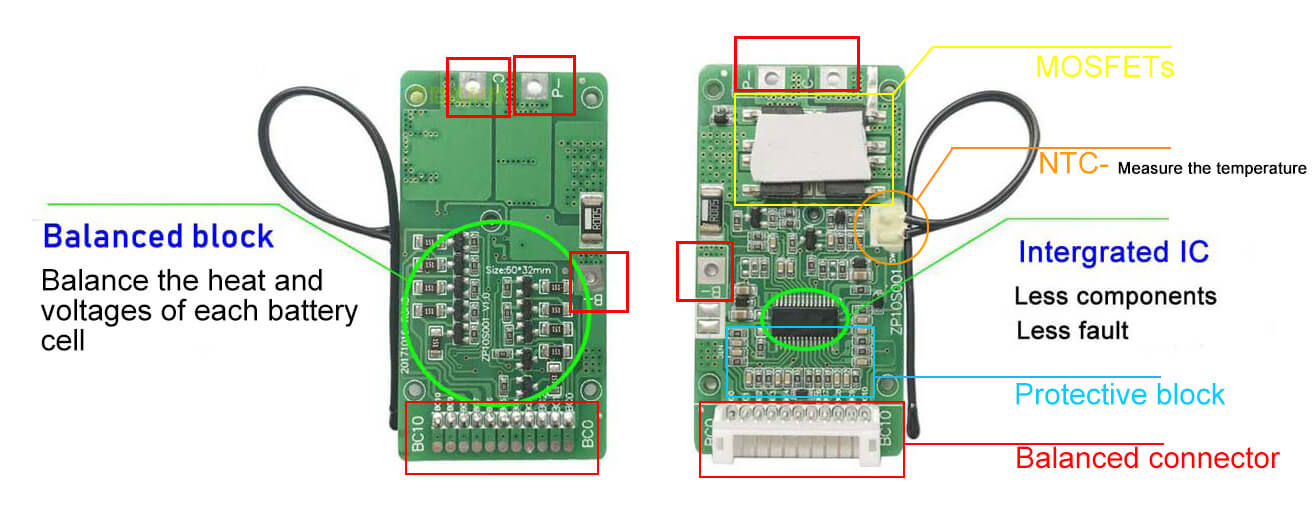

The balanced connector connects to each battery cell series of the battery pack.

By having a look at the components under the microscope, we can for one see a bunch of components like capacitors and resistors and transistors, which will protect each battery cell series from overcharge, over-discharge, and over-current.

By Flipping the PCB around, we got more components near the balanced connector, which act as the balanced module. Its job is to activate the transistor. Which then discharges one battery cell through a resistor as soon as the cell voltage goes above a certain voltage value. This way, after the charging process, all cells of the battery pack get charged up to 4.2V and we got a balanced pack.

We could see some MOSFETs ( 6 or 9 or 12 or more MOSFETS) and some transistors and resistors which act as a current shunt. As the battery draws more than the BMS max current such as 15 amps, we got a voltage drop high enough across the current shunt to activate the passive components network and thus turn of the MOSFETs and therefore the current flow.

This way the three functional groups of the BMS fulfill all the required battery pack protection features. Pretty much all the other BMS followed the same PCB principle.

How to Choose Battery Management System (BMS)

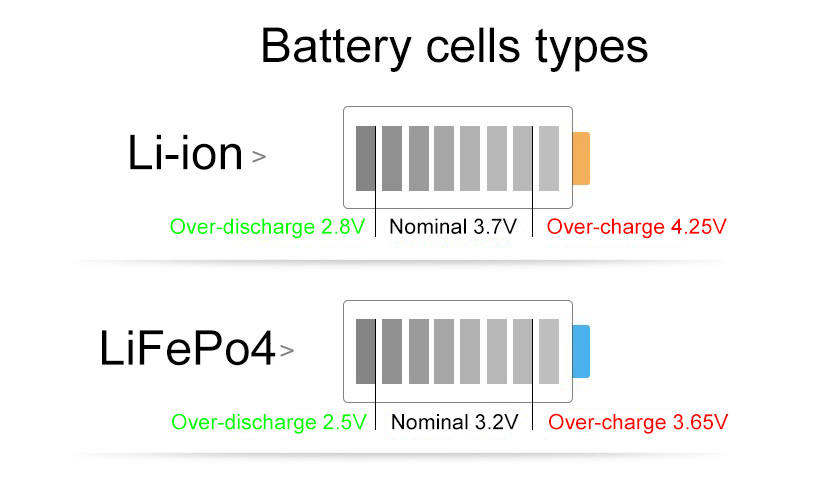

- Confirm what type of your battery is, Li-ion battery or LiFePo4 battery.

You could confirm them by reading or measuring the voltage of the battery cell. The Nominal voltage of a Li-ion battery is about 3.7V, The Nominal voltage of a LiFePo4 battery is about 3.2V. Also, you could confirm it from the supplier.

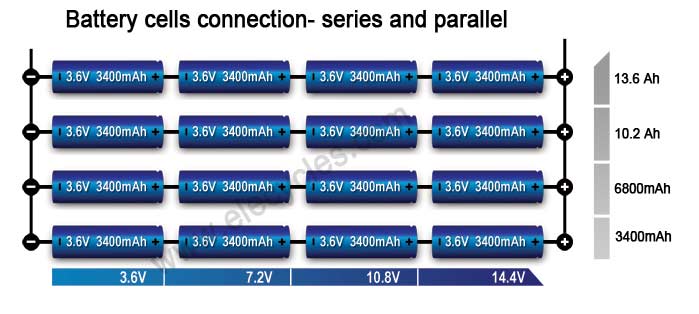

- Confirm the series of your battery

You need to confirm how many series is your battery, but not the overall voltage, because the total voltage might be the with different battery type, for example 9 series Li-ion battery overall voltage might be the same as the 8 series LiFePo4 battery.

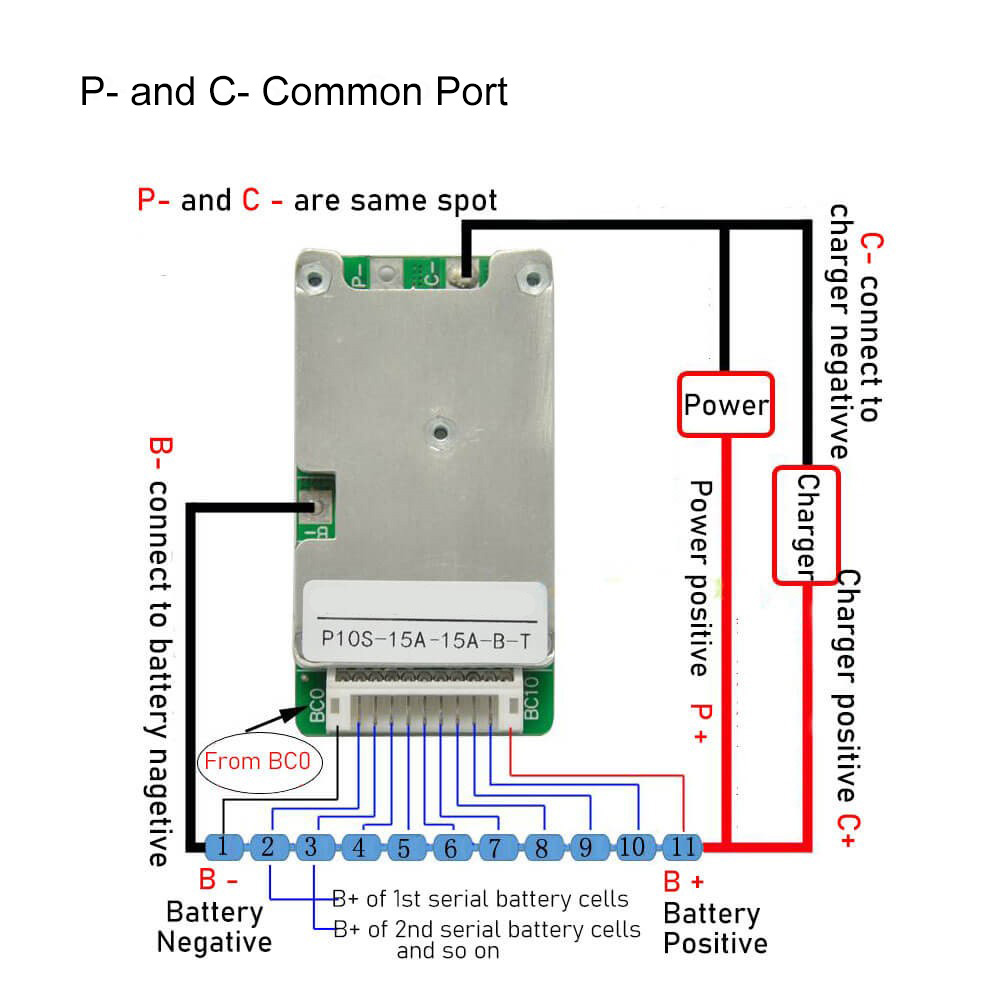

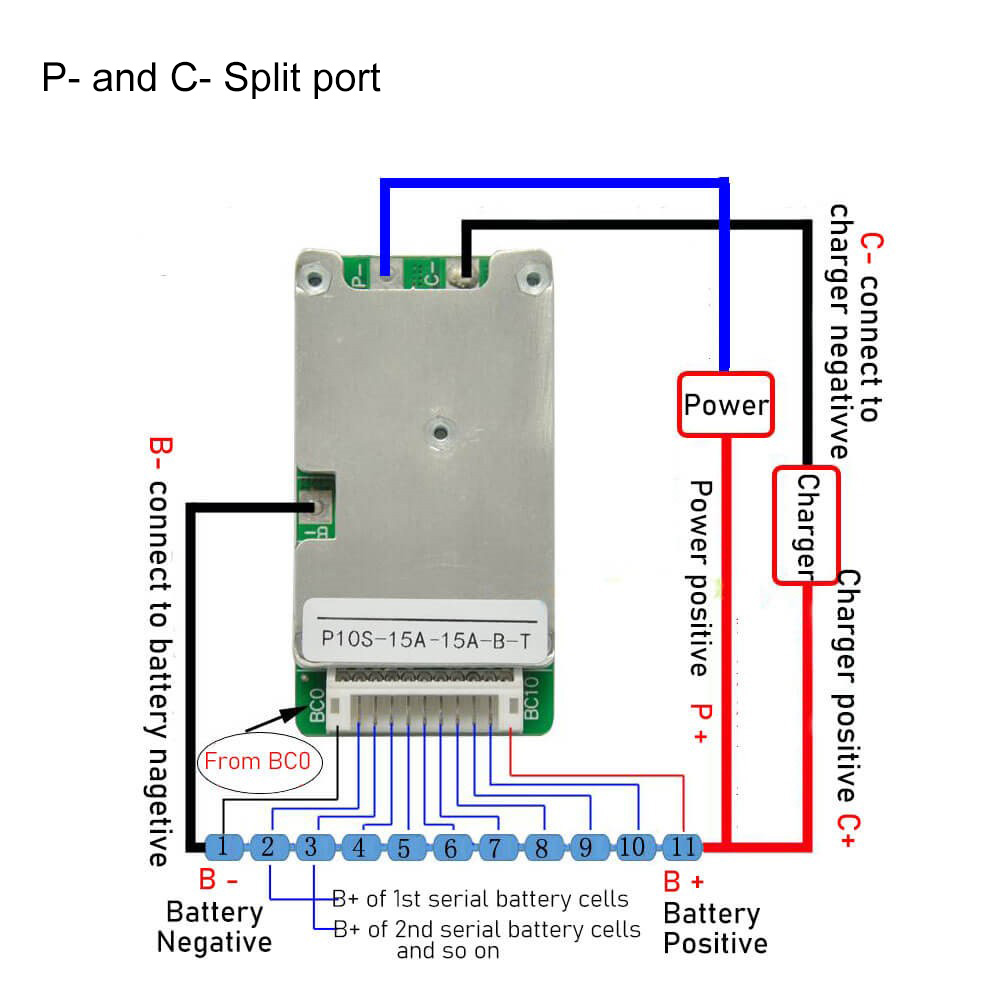

- Confirm if it is Common Port or Split Ports for the charge and discharge

Common Port means the Charge ( C- ) and the Discharge ( P-) are the same spot ( One spot), the charging current is the same as the discharging current. There are 2 wires. The Power MOSFET are the same for the charge and discharge control that leads to higher heat and resistance.

Split Ports means the Charge ( C- ) spot is different from the Discharge ( P- ) spot, the Charging current is different from the discharging current. There are 3 wires. In general, the battery charge current is much lower than the discharging current, it can shut off charging when the charging current is too high.

- Confirm the BMS current, 15A, 30A, 40A or others?

When choosing the BMS current, you should consider the matching of the motor power and the controller current. Generally, 250W would choose 15A or 20A, 350W would choose 20A, 500W would choose 30A, 800W would chooses 40A, 1000W would choose 45A or bigger. The Continuous current of BMS should be bigger than the max current of the Controller.

- Confirm there is the Balance function.

The battery cell will discharge through a resistor as soon as its voltage goes above a certain voltage value ( Li-ion battery cell is above 4.18V, LiFePo4 battery cell is above 3.16V ). It will charge and discharge at the same time while the other cells which are lower than that voltage value charge only. This way, after the charging process, all cells of the battery pack get charged up to 4.2V and we got a balanced pack.

But the Balance function will be helpless if the battery cells voltage difference is too large.

The balance function is very important for the battery cells. There are no the same battery cells because the internal resistance, self-discharge current, the capacity of the battery cells are different. The Balance function will help to decline the SOC (State Of Charge) difference of all the battery cells. Without the balance function, the difference of each series battery cells voltage may be large, which will lead to different problems such as shorter charging time, shorter distance, power shut off at the start, etc.

How to Connect Battery Management System (BMS)

Important!

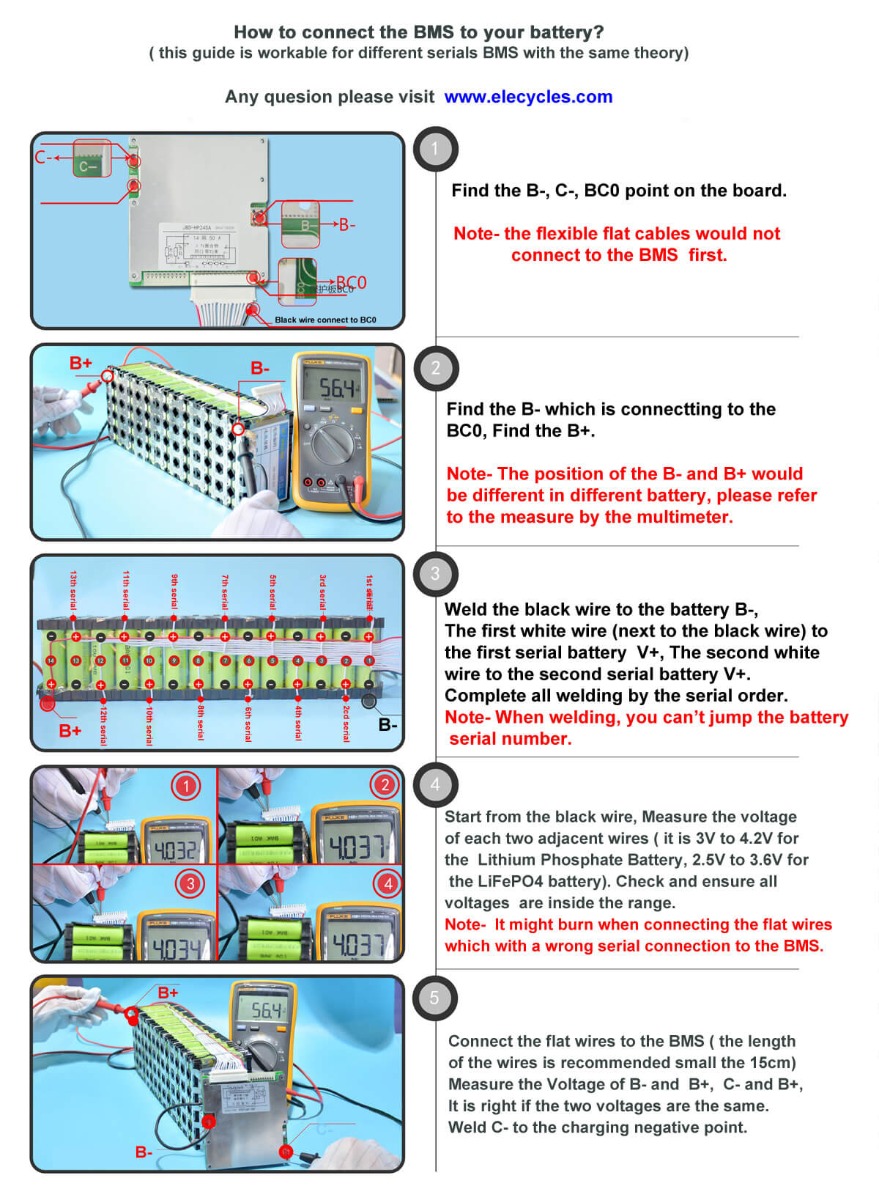

- The flat wires from different manufacturers may be different, please use the Original matching wires.

2. Please disconnect the BMS before all flat wires weld to the battery cells.

3. Please measure each series of batteries voltages and confirm right before connecting the flat wires to the BMS.

Here are the steps of connecting the BMS.

Sign In

Create New Account